Optoelectronic components: Difference between revisions

| Line 76: | Line 76: | ||

==Image sensors== | ==Image sensors== | ||

Until semiconductor image sensors started to appear in the 1990's, all TV and video cameras used vacuum tubes to capture images. Like an old fashioned [[Glossary:CRT|CRT]] (used in TVs before flat screens became available), these used a scanning | [[File:Ccd-sensor.jpg|thumb|right|An image sesor on a flexible circuit board.]] | ||

Until semiconductor image sensors started to appear in the 1990's, all TV and video cameras used vacuum tubes to capture images. Like an old fashioned [[Glossary:CRT|CRT]] (used in TVs before flat screens became available), these used a scanning electron beam to read out the brightness of the image at each point. There were various different types of [[wikipedia:Video_camera_tube|video camera tube]] but you are never likely to see any of them today outside a museum. | |||

All image sensors today consist esentially of a large array of photodiodes fabricated on a single silicon chip. A colour image sensor will have separate photodiodes for each of the three primary colours. There are two types: | All image sensors today consist esentially of a large array of photodiodes fabricated on a single silicon chip. A colour image sensor will have separate photodiodes for each of the three primary colours. There are two types: | ||

* In CMOS sensors the pixels are read out by row and column in the same was as the pixels are addressed in a flat screen display. These are the cheaper sort and use the least power and hence are used in the majority of still cameras and webcams. | * In CMOS sensors the pixels are read out by row and column in the same was as the pixels are addressed in a flat screen display. These are the cheaper sort and use the least power and hence are used in the majority of still cameras and webcams. | ||

* CCD or Charge Coupled Devices read out the data by passing a charge from each pixel along its row (or column) to the end, like a bucket brigade. This requires less circuitry per pixel for the readout and hence allows more area for collecting light, and so is used in high end cameras. | * CCD or Charge Coupled Devices read out the data by passing a charge from each pixel along its row (or column) to the end, like a [[wikipedia:Bucket-brigade_device|bucket brigade]]. This requires less circuitry per pixel for the readout and hence allows more area for collecting light, and so is used in high end cameras. | ||

==Displays== | ==Displays== | ||

Revision as of 21:17, 21 May 2023

This page covers components which emit or detect light, or change their appearance under the control of an electrical input: how to recognise them and understand how thy might fail.

Summary

Of all our senses, sight is our richest source of information about the world around us. Naturally, then, this is often the best way in which electronic devices can communicate with us. This can be using simple indicator lights through to highly complex large format diplay screens, and can embody several different technologies. Conversly, our gadgets often need to detect light, whether just to sense when a beam has been interrupted for example by closing a lid, or in order to image a scene as in a camera. Again, several principles are used across different devices.

In total, this amounts to a fair number of different types of component, but it's generally easy to identify them, to understand what they're supposed to be doing, and whether they are indeed doing it.

Emitters of light

Filament bulbs

Filament bulbs consist of a very fine coiled tungsten wire which glows white hot when a current is passed through it. A glass envelope containing an inert gas protects it from very quickly burning out. Filament bulbs are very inefficient and so can no longer be sold for domestic lighting.

Quartz halogen bulbs are similar but have a fused silica envelope which contains a small quantity of a halogen gas. This combines with the tungsten as it gradually evaporates from the filament, and decomposes when it comes into contact with the hot filament, depositing the tungsten back on it. As a result, the filament can be run significantly hotter without shortening its life, increasing its efficiency and producing a whiter light. Even so, the efficiency is not great. Often, the silica envelope is itself enclosed in a glass bulb as it can become very hot.

You will sometimes come across small low voltage filament bulbs, either with a screw base, or wire-ended and only a few millimeters in diameter.

Neon bulbs

Before LEDs became cheap and common, a neon bulb would very often be used as a power-on indicator. A common form consists of two electrodes sealed inside a 5mm glass tube containing a trace of neon gas. When lit, it gives a gently orange glow. Other clours are sometimes seen, in particular green. These either use a different gas which naturally glows green, or a gas producing blue and ultraviolate with a phosphor coating inside the glass which glows with the required colour.

Neon bulbs may require over 100V in order to light, but then operate at a voltage of around 30% less. With the added fact that they work equally with AC or DC, they are very easy to operate from the mains. All you need is a 1MΩ resistor in series to limit the current. On no account must this be omitted!

LEDs

LEDs or Light Emitting Diodes have become ubiquitous since they first appeared in the 1970's. For many years only infrared, red and green were available, with the first practical blue LEDs appearing only in the 1990's, and then violet and ultraviolet. LEDs are essentially no different from other semiconductor diodes except that instead of (most often) silicon, they use semiconductor materials with particular quantum mechanical properties causing the energy lost by electrons passing through them in a forward direction to be released as photons of light rather than as heat.

LEDs come in many different forms. As electronic components, the 3 or 5mm clear or coloured packages are most familiar but other shapes and sizes are available. Sometimes these contain 2 or 3 LED chips emitting different colours and with up to 4 wires, allowing different colours to be produced. Much smaller surface mount LEDs are often found on circuit boards adjacent to a lens or light pipe allowing their glow to be seen on the outside of an appliance.

In COB or Chip On Board LEDS, several or many blue LED chips are mounted directly on a circit board and covered with a phosphor which converts the blue to white light. In "filament" LED light bulbs the LED chips are mounted on a thin flexible strip, sometimess bent into a spiral for aesthetic effect.

Lasers diodes

There are many types of laser but their defining property is that they produce light in which all the light waves are lined up perfectly into a single beam. Think of the single continuous tone produced by an organ pipe as opposed by the hissing sound of an escape of high presure air.

An LED can be specially constructed so that much of the light is bounces back and forth between two reflecting surfaces like sound in an organ pipe. Fed with a fairly high current, this can produce laser light instead of the disorganised light that a LED normally produces as electrons pass randomly through it.

The current through a laser diode has to be controlled within fairly precise limits. Not enough and it simply won't "lase", too much and it will be destroyed by the heat generated. Consequently a laser diode is normally housed in a metal can with a glass window allowing the heat to be carried away and the light to escape, and also containing a photodiode (see later) to monitor the light output. This allows the controlling circuitry to supply sufficient current but not too much.

Light detectors

Photo-diodes and photo-transistors

A diode only conducts in one direction, but in the reverse direction, if you shine a light on it the light will release electrons, enabling a small current to flow. Most diodes come in an opaque housing, or else the light-sensitive region is so small that the effect is minimal, but a photodiode by contrast is constructed so as to maximise the effect.

A junction transistor consists essentially of two diodes in close proximity such that a small current passing through one allows a much larger current to flow through the other. Exposed to light, this is equivalent to a photodiode connected to a transistor to amplify the photodiode's current.

Two transistors can be connected in a "Wikipedia:Darlington_transistorDarlington pair" in which the second transistor further amplifies the current from the first. If the first is a photo-transistor theresult is a darlington photo-transistor with still greater sensitivity.

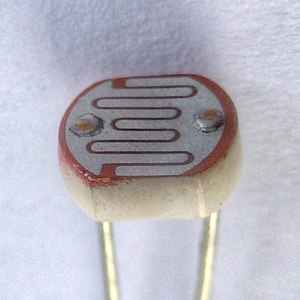

Light-dependant resistors (LDRs)

A Light Dependant or Photo Resistor uses a semiconductor such as cadmium sulphide which, in the dark, has few electrons free to carry a current and so has a high resistance. If you shine a light on it, more electrons are released and so its resistance is reduced. Unlike a photodiode, it's a pure resistance, conducting equally in either direction.

The use of cadmium is now restricted on account of its toxicity and so LDRs are most likely to be found in older equipment. They were frequently used in photographic light meters, to control street lights, night lights and the brightness of a digital clock with a LED-based 7-segment display. They have also been used in musical equipment. Some kind of vane actuated by a foot pedal controls the amount of light from a lamp falling on an LDR, which in turn controls the volume or other characteristic of the music. This avoids any crackling that a potentimeter used for this pupose might produce after heavy use.

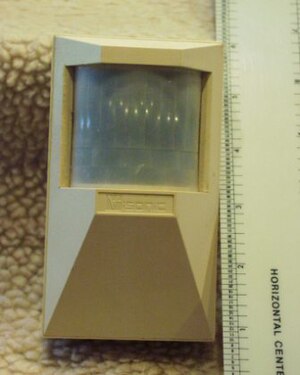

PIR detectors

Passive Infra-Red or PIR detectors work on a principle related to the piezoelectric effect, in which a strain applied to certain types of crystal slightly displaces the positive and negative charges within it, creating a net voltage across opposite faces. In the pyroelectric effect, this strain is produced by the very slight warming produced by infrared (heat) radiation. In a PIR detector, a number of plastic lenses are placed in front of a pyroelectric sensor causing multiple images of a warm body to move across the sensor as the warm body (a person, an animal or a vehicle) moves across its field of view. In fact there may be two sensors and the detector may be designed to detect differences between their outputs, reducing false detections which might be caused by environmental or electrical effects affecting both equally.

Optical sensors

Optical sensors are often used to detect a mechanical condition, such as as a lid being closed, a finger guard in place, a moving part being at the limit of its travel or the motion of a wheel. This can be done with a LED and a light detector such as a photodiode, phototransistor or photo Darlington, but for convenience, the two are often packaged together. Very often an infrared LED is used as photodiodes and their cousins have good senstivity in the infrared.

There are two types. In the reflective type the LED and light detector face the same way in order to detect a reflective surface in front of them. In a transmissive one, they face each other across a gap. These are very common in older mechanical mice, in which a wheel with slots in it is placed in the gap in order to sense its rotation as the mouse moves.

There are other types of optical sensor for more specialised purposes, for example three light sensors covered by three different coloured filters can be used to determine a colour, or the colour temperature of alight source or a scene.

Opto isolators

Sometimes it's necessary to electrically isolate one part of a circuit from another. This is easily done, as in an optical sensor, with a LED and a photo detector mounted in a single package. As with an optical sensor, the photo detector can be a phototransistor or photo darlington, or if the intention is to isolate a purely digital (on/off) signal, there may be additional circuitry included to further condition the output.

Opto isolators commonly come as a 4 or 6 pin dual-inline package just like a simple IC.

Opto isolators are extremely common in switch mode power supplies. Isolation of the output power from the mains input is achieved with a transformer but feedback is required from the output to the input in order to regulate the power so as to produce a constant output voltage. If you look inside such a power supply you will find the transformer and an opto isolator both straddling a very clear demarcation on the board between all the circuitry directly fed from the mains and all the circuity feeding the output.

Musical instruments with a MIDI interface (allowing them to be connected to MIDI synthesisers, sequencers and other instruments) always contain an opto isolator on the MIDI input, as required by the MIDI specification. This elimintes the risk of ground loops, or spurious currents flowing between different pieces of equipment, each with its own mains mower supply.

Image sensors

Until semiconductor image sensors started to appear in the 1990's, all TV and video cameras used vacuum tubes to capture images. Like an old fashioned CRT (used in TVs before flat screens became available), these used a scanning electron beam to read out the brightness of the image at each point. There were various different types of video camera tube but you are never likely to see any of them today outside a museum.

All image sensors today consist esentially of a large array of photodiodes fabricated on a single silicon chip. A colour image sensor will have separate photodiodes for each of the three primary colours. There are two types:

- In CMOS sensors the pixels are read out by row and column in the same was as the pixels are addressed in a flat screen display. These are the cheaper sort and use the least power and hence are used in the majority of still cameras and webcams.

- CCD or Charge Coupled Devices read out the data by passing a charge from each pixel along its row (or column) to the end, like a bucket brigade. This requires less circuitry per pixel for the readout and hence allows more area for collecting light, and so is used in high end cameras.

Displays

7 segment, dot-matrix

LCD

Plasma

OLED

Vacuum fluorescent

E-ink

DMD

And now ...

... you might like to continue by reading about Passive components.