Digital weighing scales: Difference between revisions

| Line 7: | Line 7: | ||

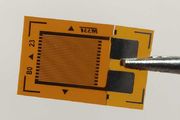

[[File:Img_1715a.jpg|180px|thumb|left|A resistive strain gauge.]] | [[File:Img_1715a.jpg|180px|thumb|left|A resistive strain gauge.]] | ||

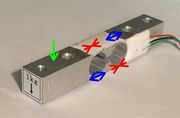

[[File:Img_1725a.jpg|180px|thumb|right|A bar-type full bridge load cell.]] | [[File:Img_1725a.jpg|180px|thumb|right|A bar-type full bridge load cell.]] | ||

Domestic weighing scales use strain gauges to measure the tiny deformations of a piece of metal under load. | |||

A strain gauge is extremely simple. A zigzag resistive track on a foil backing is elongated and becomes thinner as it is stretched (within its elastic limit), which increases its resistance. Conversely, if it is compressed (so long as it doesn't buckle), its resistance is reduced. | |||

Foil strain gauges like the one shown are normally very securely glued to a piece of aluminium or steel and covered by a protective layer. This causes them to stretch or be compressed with the metal they are mounted on. | |||

A strain gauge will also change its resistance with temperature, and induced hum from nearby mains electric devices may completely swamp the tiny change in resistance. For these reasons, strain gauges in weighing scales are always used in pairs or or in fours comprising a "load cell", with pairs on opposite sides of a piece of metal, causing one to be stretched while the other is compressed. The difference between their resistances is then measured rather than an absolute resistance, allowing other effect to be cancelled out. | |||

A bar-type load cell is shown in the photo on the right. This has 2 strain gauges on the top and two on the bottom. | |||

At first sight, applying a load to it (the green arrow) would cause the top two strain gauges to be stretched and the lower two to be compressed as the bar is bent into an arc. Furthermore, they would be stretched or compressed more the nearer the end of the bar the load is applied. | |||

[[File:Img_1727a.jpg|180px|thumb|left|A half-bridge load cell - top.]] | [[File:Img_1727a.jpg|180px|thumb|left|A half-bridge load cell - top.]] | ||

[[File:Img_1728a.jpg|180px|thumb|right|A half-bridge load cell - bottom.]] | [[File:Img_1728a.jpg|180px|thumb|right|A half-bridge load cell - bottom.]] | ||

Revision as of 22:04, 22 August 2017

This page covers digital kitchen and bathroom scales. Digital luggage scales follow the same principles of operation.

Summary

There isn't much to go wrong inside digital weighing scales apart from physical problems which should be visible on close inspection. Nevertheless, their principles of operation is interesting, and an understanding will help diagnose any faults which aren't visually obvious.

Principles of operation

Domestic weighing scales use strain gauges to measure the tiny deformations of a piece of metal under load.

A strain gauge is extremely simple. A zigzag resistive track on a foil backing is elongated and becomes thinner as it is stretched (within its elastic limit), which increases its resistance. Conversely, if it is compressed (so long as it doesn't buckle), its resistance is reduced.

Foil strain gauges like the one shown are normally very securely glued to a piece of aluminium or steel and covered by a protective layer. This causes them to stretch or be compressed with the metal they are mounted on.

A strain gauge will also change its resistance with temperature, and induced hum from nearby mains electric devices may completely swamp the tiny change in resistance. For these reasons, strain gauges in weighing scales are always used in pairs or or in fours comprising a "load cell", with pairs on opposite sides of a piece of metal, causing one to be stretched while the other is compressed. The difference between their resistances is then measured rather than an absolute resistance, allowing other effect to be cancelled out.

A bar-type load cell is shown in the photo on the right. This has 2 strain gauges on the top and two on the bottom.

At first sight, applying a load to it (the green arrow) would cause the top two strain gauges to be stretched and the lower two to be compressed as the bar is bent into an arc. Furthermore, they would be stretched or compressed more the nearer the end of the bar the load is applied.