Personal e-transport

This is currently a skeleton page. Please help by adding your contributions either here or in the associated Discussion page.

This page will cover e-bikes, e-scooters, hoverboards and similar battery-powered personal transport devices.

Summary

These devices all contain a battery, controls and/or sensors, control electronics, charging electronics and a motor. Your first task may be to determine which of those needs attention.

Safety

- These items come with a fairly powerful rechargeable lithium battery. Physically or electrically abused, these can present a serious fire risk. If refurbishing a battery with new cells it's essential that you understand how to correctly charge and balance the cells.

- The motor is likely to be quite powerful and the associated gears could cause serious injury to fingers if it started unexpectedly. Disconnect the battery as the first thing you do and reconnect it only at the end. If batteries are swollen do not try to puncture them or connect them as they are probably prone to explode. Try to disconnect them and remove them from the vehicle as gentle as possible. Try to find a proper way to dispose of lithium batteries through your local facilities as they can be harmful to the local environment if they are improperly disposed of.

Main section

Electric Motor Problems:

Electric Motor Problems:

Electric Motor Problems

Eoblems:Electric Motor Problems:

Brushed or Brushless DC electric motor?

Most electric scooters, bicycles and hoverboards use brushless motors. If your vehicle has a brushed DC motor then changing the graphite brushes regurarly to avoid sparks and damage to your motor's winding should be a part of your maintenance every once in a while.

Identify the electric motor or motors of your vehicle:

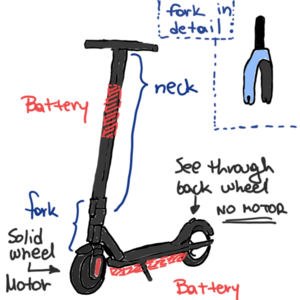

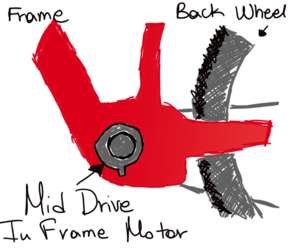

- In electric scooters the motor is embedded within the wheel usually leaving no room for air to pass through the wheel. Identify whether the back or front wheel is the one powered from the motor. In certain cases it might be both.

- In hoverboards it's usual for both wheels to have embedded hub motors in their wheels.

- In electric bikes the motor can be either embedded within the frame close to the pedals, or can be found at most commonly on the center of the back wheel.

Is there a grinding sound when the motor turns on?

If the motor doesn't spin freely but a grinding noise exists you might have a bad bearing that needs changing. You need to dissasemble the wheel to reach the bearing most of the time and then replace with a new bearing with similar dimensions that you'll regrease. Reassemble the wheel and check if the grinding noise is gone. If there is a not uniform grinding noise that speeds up as the hub motor speeds up and the hub motor has an embedded disc brake in its wheel you should check to see if the disk brake alignment is correct.

Does the motor vibrate or shake then powered on?

If the motor vibrates or shakes when turned on then perhaps the motor has internal issues like sparks appearing or power supply you are using can't properly power the motor with the needed amperage. Reassemble the vehicle completely, and connect the battery to see if the battery reading fluctuates at the display during the startup of the motor, if the motor keeps vibrating then it's either a faulty battery or controller since both provide and check that the motor has the necessary amperage to reach its max speed.

Are you planning on powering the motor from a power supply?

To move a motor intended for electric vehicles you need a power supply capable of outputting voltage and current as the vehicle's battery's characteristics which are usually written on the battery. If you are not comfortable dealing with voltages in the field of 12, 24, 36 or 48 Volts please address a proper repair facility in your area to help you diagnose your vehicle. If you are a person familiar with handling equipment at these voltages, identify the negative and positive terminal in which your battery connects to and apply voltage through an appropriate power supply to move the electric motor. If the motor does not move, try giving it a spin first by hand. Turning the motor by spinning the wheel helps the motor start, since electric motors can demand three times the normal current value during starting. By turning the motor, you avoid those big starting current loads to your power supply.

Electronic problems:

How do I dissassemble or take apart my vehicle to reach the inside electronics?

After you've identified the electric motor or motors in your vehicle try to find a video or written tutorial showing how to take apart your electric vehicle and follow it closely. Since you are dealing with batteries containing high voltages and a lot of wiring, a tutorial is your best bet against causing extra damage to the vehicle from improperly dissassembling it. Remove the battery as soon as possible without damaging your vehicle to ensure your safety.

How do I choose a replacement speed controller board for my electric motor?

If you looking a controller for your electric vehicle in general you need a controller capable of handling the output current and voltage that your battery outputs. This is usually written on a label on the battery itself or the owners manual. Choosing a speed controller that can provide more amperage than your current one means you have a faster final motor speed but your battery will deplete faster and need to be charged more often. For lower amperage speed controller boards the opposite is true, meaning that lower amperage means a lower final motor speed and slower overall vehicle but your battery won't deplete as fast. Make sure if you are replacing the controller boards that they are fitted the same way the were before they were removed because if the thermal paste doesn't come in contact with the aluminum frame the controller board will heat up as it is handling high amperage and the electronics inside it may become unusable.

How can I check if the electronic circuits still work in my electric vehicle?

If you know how to use continuity mode in your multimeter checking the printed circuit boards available to you might be useful especially if you can identify potential dead shorts, grounding faults or other apparent faults of the controller board. If the controller boards are covered with silicone, often a procedure that helps with waterproofing them, and a continuity check is not possible try a visual check of the board to make sure that no part seems to show water damage, signs of burnt or improper soldered intergrated circuits. Keep in mind that controller boards often drive the display, the electric motor and other systems in your vehicle to understand what can easily be replaced or not.

What is the gray paste on top of my speed controller?

Since speed controller electronic boards usually handle high voltages and amps they usually heat up quickly and need some form of thermal management to keep cool and working efficiently. Sometimes thermal paste, yes like the one used for computer CPUs, can be applied to one side of the controller boards for them to dissipate heat along the aluminum frame of the electric scooter, under the part where the user usually stands. This is usually the case in electric scooters but I am not aware if hoverboards, or electric bikes follow the same principle.

How to tell if moisture is the cause of concern for your vehicle's electronics?

Most electric vehicles feature moisture detection strips that turn pink in the presence of moisture. If you encounter those strips while opening the vehicle's electronics enclosure and see they have turned into a pink color you might be dealing with moisture or humidity damage to your electronics. If the enclosure also contains the battery of the vehicle visually check its plastic cover to see if it's broken or teared up. If that covering is torn apart or open somewhere, moisture might have gone to your battery.

Mechanical Problems:

Does the electric scooter drive in a curved line, feels unsafe or you want to check its alignment?

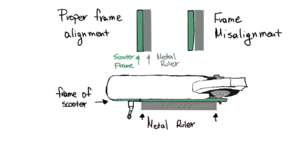

If the electric scooter doesn't keep a straight direction when you are driving in a straight line as much as possible you can check the alignment of the back wheel with the frame. To do that put a metal ruler across the frame with the ruler touching as much of the lower frame chassis and the motor wheel bracket as much as possible. If the metal ruler touches the entire frame and back wheel bracket in a uniform way without gaps then you are in luck because the scooter is properly aligned. If there are small gaps between the frame or bracket of the wheel and the metal ruler then that means that possibly the fork of the scooter is possible not straight due to a collision or other mechanical reason and needs replacing. In this case, I define as the fork of the scooter as the mechanical part that is holding together the neck of the scooter with the lower chassis containing usually the battery and wheels.

Does the neck of an electric scooter feel unsafe, or wiggles back and forth?

The neck of the scooter which connects the steering wheel and lower chassis of the vehicle shouldn't wiggle back and forth or feel unsafe. If it does wiggle and not just turn right and left securely, there might be some issue with the metal chassis of the neck of the scooter or fork. Once again, I define as the fork of the scooter as the mechanical part that is holding together the top part of the scooter or neck that contains the steering wheel and controls, with the lower chassis that usually contains the battery and wheels.

A metal part of my electric scooter has been broken and I urgently need my vehicle fixed:

Sometimes mechanical parts connecting the frame together like the fork or neck of an electric scooter might bend or break. In that case, you can get an appropriate replacement from a trusted seller but that might take some time you don't wish to spend without a working vehicle. For metal or mechanical parts, asking local metalworking shops in your area, might be worth it, as they might be able to help with your problem by designing and making a replacement part themselves. Also electric scooter parts may be interchangeable from one brand to another if modified properly with professional help from metalworking and repair businesses. This isn't really recommended as a repair you should do yourself or in general but it's mentioned here as an alternative option for a temporary fix that might save you a lot of time you would otherwise wait to get an appropriate part from the manufacturer. Remember to always use caution when driving such electric vehicles that have such repair or modified parts and realise that this is perhaps one of the many ways to break any warranty you might have for the vehicle.

Basic Battery Faults Diagnosis:

I have unplugged my battery from the vehicle. How do I diagnose if it's faulty?

Start with the basics by trying to charge your battery with the official charger that came alongside your electric vehicle. Is an LED light blinking or lighting anywhere indicating the battery might be charging? If yes, charge the battery as you would, and then check with a multimeter its output voltage by connecting the multimeter to the battery's negative or positive terminal. If the reading voltage is significantly lower than the battery's characteristics you might need to get a new battery or have it fixed by a professional repair shop. If you have physical access to the battery's BMS board that controls the cell's charging and discharging and own a multimeter, try without touching any of the battery's cells or contacts to measure the width of the wire connecting the BMS board to the individual cells. Often BMS manufacturer's will use the thinnest wires according to standards which leads to bad connections or the BMS losing efficiency quickly. If that's the case for you and according to a DC wire size calculator and your multimeter reading you find that the wire's thickness isn't enough to handle the voltages needed for your vehicle please contact a technician to solder a new quality BMS to your battery. If you do not have easy physical access to the BMS or the battery please do not attempt this, as it could lead to serious hazard to yourself or others.