Connecting and joining wires

This page covers how to safely and reliably connect, splice or join wires together.

Summary

Often during a repair, wires need to be connected or reconnected. Perhaps a worn out flex is being replaced or a failed thermal fuse. Simply twisting the wires together would hardly ever be a good idea, but there are several other ways of doing it.

If you are regularly doing repairs then you may find it useful to keep a few connectors of different types in your tool box.

Safety

- Where the wires carry mains voltage it's essential that the join is properly insulated.

- If the join may come under strain then the wires should be clamped in some way to prevent the join from pulling apart. This is essential in the case of mains voltages.

Fix it before it breaks!

A very common fault is a broken headphone lead at the point where it enters the jack connector. If the outer insulation is starting to crack, you're on borrowed time! A simple solution is to repair it with Sugru. This comes in a mouldable putty-like form and sets within 24 hours to synthetic rubber. Mould a little around the cable to protect the damaged section, moulding it onto the connector to prevent movement and thinning progressively away from the connector so avoiding any point at which he cable can be sharply bent.

Screw and spring terminals

Probably the oldest method of connecting a wire is with a screw terminal. The screw head may hold the wire directly or preferably under a washer, or the screw may clamp the wire in a hole in a brass terminal.

In the case of stranded wire, always keep the individual strands together after stripping the insulation by firmly twisting them together, or better still, applying a little solder.

In the first case, make sure the bare end of the wire is at least long enough to make a half tun around the screw, and always wrap it round the screw in the same direction as you will be tightening it.

Where the screw clamps the wire in a hole n a brass terminal, it's often helpful to strip sufficient insulation so that you can fold the bare end double, so giving the screw plenty to grip on. Alternatively, apply solder to stranded wire.

Joining mains cables

The only way to safely join two flexible mains leads is with an in-line screw terminal connection box. This has a cable clamp at each end which must be used to clamp the outer insulation, not just the inner wires.

Electricians often use a circular junction box without cable clamps, but this is only acceptable where all the cables entering it are secured along their length with cable clips, often nailed to a joist.

Choc block connectors

These come in strips which can be easily cut according to the number of wires you need to connect. They are useful for connecting low voltage wires but offer no form of cable clamp so you should ensure that the cables cannot be strained. They contain a hole between each pair of connectors, which you can use to screw them down to a firm base.

Choc block connectors come in various sizes such as 3A, 5A, 15A etc., but the only important thing is to ensure that they are big enough to take the wire, but at the same time, the wire is big enough to be gripped by the screw. You can always strip a little extra insulation and fold the wire double to give the screw more to grip.

Spring terminal connectors

There are several types of these, and they can be used to make a quick and easy connection without any tools (except for stripping the insulation). They are often used for loudspeaker cables and in model train sets, providing a simple way for connections to be made or removed as often as needed. Applying solder to the bare end of stranded wire is helpful.

Soldering

Twisting the wires together and soldering is often the best method, but there are two ways of doing this. If possible, you should twist the wires in-line before soldering as this makes a stronger (and neater) join than twisting the ends together. This requires a greater length to be stripped of insulation and can be tricky if the wires differ in diameter, or if one is stranded and the other solid.

The wires need to be clean in order to make a good joint. A little extra flux from a flux pen never does any harm and often makes it easier if the insulation has not been freshly removed. In the case of enamelled wire, the enamel needs to be scraped or burnt off. If a little remains it often won't matter and may melt with the solder. In fact some wire enamels are "solder-through" and designed to melt with the solder, but an initial scrape to get it started usually helps.

Soldering headphone leads

Headphone leads use a special kind of ultra-flexible wire consisting of individually enamelled strands. The two connections (to each earpiece) or three (to the stereo plug) use different coloured enamel. You will need to separate the strands of each colour.

The enamel is generally designed to melt in the solder but it often helps to start it off by gently scraping with a knife, trying not to break any of the strands as you do so. Alternatively you may be able to burn it off in a flame.

Heat shrink solder sleeves

A simple solution if you don't have a soldering iron handy is to use heat shrink solder sleeves. These contain a ring of low temperature solder in the centre of a heat shrink tube. Make sure the stripped ends of the wires are clean so as to accept the solder. Pass one wire in each end so that they cross over in the solder ring, then simply apply a heat gun. This simultaneously melts the solder and shrinks the sleeve to insulate the join.

Crimping

Crimping is both quick and easy, and makes a very reliable join, creating microscopic welds between the wire and the connector. But it does require the correct crimp connectors and crimping tool to make a good join. A crimping tool and a selection of crimp connectors are not expensive.

Crimp connectors come in several colour-coded sizes and it's important to use the right one. Too small and you won't be able to insert the wire, or too big and it may not be gripped properly. In addition to in-line connectors, an assorted set will usually contain a variety of spade, ring and bullet connectors as widely used in auto electrics.

Some crimp connectors such as the one illustrated have a heat shrink sleeve. This can be recognised by the noticeably larger diameter of the sleeve at the two ends. When shrunk with a heat gun this seals around the wires at each end (provided they're not too thin), giving extra protection to the two wires being joined.

Another type of crimp connector has a blind hole into which both wires to be joined are inserted together.

N.B. for safety, always give a crimp connection good tug after making it to ensure it's a good one.

DIY crimping

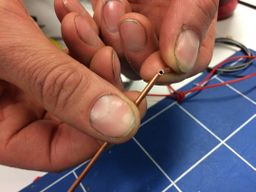

Standard crimp connectors most commonly come in the larger sizes used in auto electrics, but these may be too large for some of the wires used in domestic electrical appliances and gadgets. An example is if you need to replace a wire-ended thermal fuse in a hair dryer, steam iron or kettle. Soldering may not be advisable as the heat from the soldering iron may cause the replacement thermal fuse to blow.

An alternative is to use narrow gauge copper or brass tubing as available from model making suppliers. Choose a size into which the wire fits comfortably. Cut a short length by rolling it on a flat surface under the blade of a craft knife to score it and then snap it off. Insert one wire into each end and crush the tube onto each wire with a pair of fine-nosed pliers or blunt wire cutters (but if you use wire cutters, take care not to cut into the tubing).

N.B. The tug test is arguably even more important with a DIY crimp.

Insulation displacement connectors

Scotchlok connectors contain a piece of metal which cuts through the insulation and bites into the copper conductor. They are commonly used in auto electrics for splicing into power wires in order to supply after-market accessories. They contain two holes for two wires, one open at the side allowing it to be slipped over an existing wire, and the other a blind hole to take a lead to the accessory. Squeezing it with a pair of pliers causes the metal piece to cut through the insulation of both wires and make the connection. Folding over the flap allows you to lock it closed.

You could equally use one of these to connect the ends of two wires, but you must use the right size for the wires you are connecting in order for it to cut fully through the insulation whilst not damaging the copper wire inside.

Insulating your connections

Some types of connector are self-insulating, so long as none of the uninsulated wire is exposed, but with others you will usually need to provide some form of insulation.

- PVC tape is the simplest and easiest but not necessarily the neatest. NEVER simply bind up a cracked mains lead with PVC tape.

- Heat shrink sleeving is an excellent method. It comes in a variety of sizes and colours, pre-cut or in a continuous length. Choose a size which is no more than twice the diameter of the joint you need to insulate, and don't forget to slip it onto one of the wires before you join them! If soldering, keep it away from the iron. Once you're ready, slip it over the join and heat with a heat gun until it has fully shrunken. If you don't have a heat gun to hand, you can hold it very close above a soldering iron and it should shrink slowly, but be very careful not to let it touch the iron.

- Sugru can be used to insulate a join as described above, such as in a headphone lead, but don't rely on it alone to provide strain relief. If you need strain relief then one solution would be to knot the lead either side of the join to give the Sugru something to hold onto.

- The earth wire in the type of mains cables designed for permanent installation is often uninsulated. Green and yellow striped sleeving is available to slip over this within a mains socket or wall switch to prevent it touching a live connection. This will sometimes be useful in other circumstances, but avoid using it where might confuse the next repairer into thinking it's an earth wire when it isn't.