Bouilloires, chauffe-eau électriques et cuiseurs de riz

Cette page traite des bouilloires, chauffe-eau et cuiseurs de riz électriques, de leur fonctionnement et de la manière dont vous pouvez les réparer.

Résumé

Les bouilloires et chauffe-eau électriques sont des appareils assez simples, mais la combinaison de la chaleur, de l'eau et de l'électricité peut souvent entraîner des pannes. C'est particulièrement vrai pour les bouilloires électriques bon marché qui, malheureusement, ne peuvent pas être facilement réparées.

Il est souvent possible de retirer le socle d'une bouilloire sans fil en enlevant plusieurs vis dans le fond, bien qu’un embout de tournevis de sécurité puisse être nécessaire. Cela vous permettra de vérifier la résistance avec un multimètre et d'inspecter le mécanisme de l'interrupteur. Malheureusement, la résistance n'est généralement pas remplaçable et les défauts de l'interrupteur peuvent être dus à une petite pièce en plastique cassée, impossible à réparer. Les fuites d'eau peuvent également être difficiles à réparer, mais ce n'est pas toujours le cas et cela vaut toujours la peine de vérifier s'il s'agit en fait d'une réparation simple.

Vous aurez peut-être plus de chance avec les chauffe-eau électriques. Dans ce cas, il peut s'agir simplement d'un fusible thermique qui a sauté.

Sécurité

- Vérifiez toujours que l'appareil est débranché avant de commencer à travailler. Il pourrait être très dangereux de le tester en le branchant alors qu'il est partiellement démonté.

- Les pièces peuvent être très chaudes après la mise en marche de l'appareil. Veillez à les laisser refroidir avant de travailler dessus.

Bouilloires électriques

Beaucoup de bouilloires électriques en panne arrivent dans les Repair Cafés, mais elles sont rarement réparées. La plupart des bouilloires modernes sont sans fil et reposent sur un socle circulaire qui est relié au réseau électrique. Certaines bouilloires sans fil plus anciennes ont un socle non circulaire avec un circuit électronique sous la poignée. Les plus anciennes ont un fil détachable et une résistance chauffante visible à l’intérieur de la bouilloire, qui peut même être remplaçable. Les bouilloires plus modernes, en revanche, ont la résistance intégrée dans le fond métallique de la cruche.

Comment fonctionnent-elles ?

All automatic kettles work by providing a path for the steam, as they come to the boil, over a bimetallic strip or popping disk which bends under the heat, so flicking off the switch.

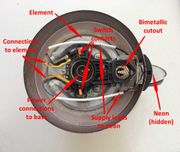

Referring to the picture, the supply from the base enters via the central pin and the circular contact around it. These are connected to the switch contacts (both live and neutral are switched) and hence through a pair of brass strips, the other ends of which are spot-welded to the ends of the element.

Wires are also taken from the brass strips to the neon, which lights whenever power to the element is switched on.

In this kettle there is probably a bimetalic strip (not visible) in the steam path which flicks the switch off when the kettle boils. A bimetallic popping disc (which pops like the safety button on the lid of a jar of jam) also flicks the switch off if the kettle overheats.

Often a kettle will also have a thermal fuse as a safety measure to switch it off if it's turned on with no water in it.

As an additional long-stop safety measure to prevent a possible fire if other measures fail, some kettles have an element which is designed to burn out before it gets dangerously hot. Unfortunately, such elements are prone to burning out needlessly. In others, a plastic is used in the switch mechanism which will soften with excessive heat, releasing the spring which holds the contacts closed and so switching the current off. You then have a dead kettle, but at least it didn't burn your house down.

Fault finding and fixing

If the kettle is completely dead, check the fuse before doing anything else. This is not often the problem but is easily checked and could save you a lot of time. Again, not often the problem, but it's also worth checking the connections from the mains plug through to the base that the kettle sits on.

Next, check the state of the contacts in the base of the kettle itself. These can sometimes get distorted or eroded by sparking, with the result that the contacts in the bottom of the kettle no longer make contact with the ones in the base. This may be puzzling at first since continuity tests on both the base and the kettle show no fault in either, yet the kettle doesn't work. You may be able to effect a fix by cleaning or bending the contacts back into shape.

Sometimes the problem is a lid which doesn't close or stay closed, and this can be a broken piece of plastic, not often repairable. There may be some screws under the lid allowing you to access the hinge or catch.

Disassembly usually starts with removal of several screws in the base. Some or all of these may be security screws to prevent unskilled tampering. The base will then come off allowing you to examine the switch, the element and any other parts.

The element is probably the first thing to check. The connections should be fairly obvious and you can check it with a multimeter on a resistance range. For a 3KW kettle it should read around 20Ω, or up to 100Ω for a small travel kettle. The element is not usually replaceable where it's built into the base.

There may be a thermal fuse to cut off the current in the event of the kettle boiling dry or being operated empty. Test it with a multimeter on a resistance range (it should record practically zero resistance). This, you may be able to replace, but make sure the replacement is rated at the same temperature and current. It's likely to be mounted so as to be in good thermal contact with the base of the jug, and a replacement must be similarly mounted.

The switch mechanism consists of several plastic and metal parts allowing it to be switched on by an external control and switched off by the bimetallic strip or popping disk. The plastic parts sometimes get broken, and here too, they are not often fixable. Sometimes, something may get dislodged and by a careful examination you may be able to see how to fix it.

Over time, the electrical contacts which close to boil the kettle may get bent and fail to connect in which case bending them back into place may fix the problem.

Water leaks are sometimes a problem, and these are hard to fix, particularly in the presence of limescale. Steam may get into the switch mechanism and causes corrosion. This too is problematical but there may be some hope if you can clean it up.

Electric urns

Catering urns, particularly the higher quality ones, may offer more hope as spare parts may be available and may not be hard to fit. Spare elements, switches, thermal cut-outs, taps and other parts may be available from a catering equipment supplier.

Fault finding initially follows the same principles as for a domestic kettle. Instead of a single use thermal fuse it may have a thermal cut-out with a manual or automatic reset. The manual reset types have a button to press which will give a definite click as it resets, but some level of disassembly is likely to be necessary to access it as the button will be very close to live contacts.

Automatic fill types of urn are designed to be plumbed in to a water supply and contain an electrically actuated stop cock. There will be sensors to detect the water level and temperature, feeding into some sort of controller which switches the element and operates the stop cock.

The controller on these may be relatively sophisticated, for example, if switched on empty it may initially fill with a small amount of water and first of all bring that to the boil. It will then top up a little at the time, bringing it back to the boil with each top-up until it's full. Since a 10 litre urn may take half an hour to boil from cold, this allows it to start dispensing boiling water much sooner.

Rice boilers

These contain a removable pan to contain the rice and the water, with a heating element beneath. The weight of the pan presses down on a switch which is only closed (enabling the heater) if the pan contains a minimum amout of water. There will also be a mechanical or electronic time switch.

As with an electric urn, there may well be a thermal fuse to protect it in the case of overheating. This may be a non-resettable type which will need to be replaced if it blows. Do not atempt to solder the replacement as the heat of the soldering iron may cause the replacement to fail. Instead, the connections must be made by crimping.

External links

- The Life Scientific: A BBC interview with John Taylor, inventor of many of the concepts used in electric kettles.