How dimmers and motor controllers work

Motor controllers and dimmers are commonly built around a simple circuit. Sometimes, this can fail, but may well be repairable.

Summary

Many household appliances such as vacuum cleaners and kitchen mixers and blenders have continuously variable speed control using a triac. Older light dimmers use the same circuit though they work poorly with low energy CCFL and LED bulbs.

Safety

- As with all mains-operated devices, an understanding of electrical safety is essential for any dissasembly or repair.

Mode of Operation

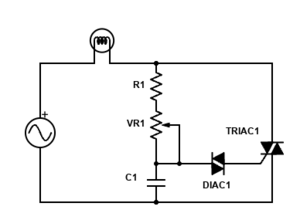

The simple circuit shown in the graphic was used in the original light dimmers often fitted in place of a normal on/off light switch for old fashioned incandescent light bulbs. The same circuit is still used in motor speed controllers in many appliances. (A more sophisticated circuit is required for modern low energy light bulbs.)

The key circuit element is a triac, a 3-terminal semiconductor device with few if any other applications. It operates as a switch, controlled by the the gate (the side connection in the diagram). Initially it allows no current to pass, but when a voltage is applied to the gate it suddenly turns on and remains on (irrespective of the gate voltage) until the mains supply drops to zero at the end of a half-cycle. A triac is in fact very similar to a thyristor or SCR (silicon controlled recitifier) except that it works equally well with either positive or negative voltages. This makes it ideal for use in AC circuits, in which the voltage reverses twice per cycle.

You will notice another component in the circuit with a similar symbol, but lacking a gate. This is a diac, otherwise similar to a triac. Instead, this turns on when the voltage across it reaches a certain value, perhaps 35V.

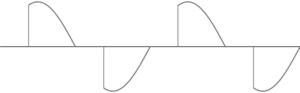

As the mains voltage rises at the start of a cycle, current flows through the resistor R1 and variable resistor VR1, charging the capacitor C1. This continues until the voltage across C1 is sufficient to turn on the diac. The capacitor discharges through the diac and into the triac gate, switching it on. It remains on for the rest of the cycle, only switching off when the mains voltage drops to zero, after which the same happens in the other half cycle. Since the power is switched on some time after the start of a half cycle (as shown in the graphic), this is know as a leading edge controller.

The lamp brightness or motor speed will depend on the propotion of each half-cycle for which the triac is conducting, determined by the setting of the variable resistor VR1 and hence the speed at which e capacitor C1 charges.

In practice, there are likely to be a few additional components to absorb spikes in the mains voltage that may otherwise cause unreliable operation or possibly even damage the triac. Electric motors are a common culprit, so a motor speed controller will always have this provision, even though a motor itself will be fitted with similar transient suppression components.

Low-energy lamp dimmers

Old fashioned dimmer switches are unsuitable for use with low energy bulbs as the electronics tend not to work well with the current being switched on suddenly in the middle of a half cycle. Modern dimmer switches operate differently, often including a microcontroller, and instead, switching the current off part way through each half cycle. These are known as trailing edge controllers and are suitable for most LED lamps specifically marked as dimmable. However, a dimmer switch may offer several modes of operation to accomodate the peculiarities of particular lamps. LED lamps not marked as dimmable will generally not work well with any type of dimmer.

Faults

In triac-based (leading edge) dimmers and motor controllers, either the diac or the triac can fail, causing a motor either to run at full speed only, or not at all. First try replacing the diac. Any with a voltage rating in the 30 - 40V range should do. If that doesn't fix it, check the markings on the triac and replace it with one of the same type.

LED dimmers may also be fixable. Check for signs of overheating, but if all appears good on the surface, components to look out for and test are diodes and/or a diode bridge (a package with 4 leads containing 4 diodes), a Class X or Y capacitor, an electrolytic capacitor, and a transistor, probably a power MOSFET. This latter is not easily tested.